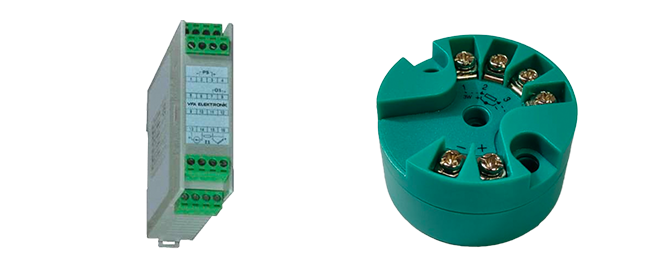

- Auto-tune PID control

- Universal Process Input (Selectable mv, V, mA, thermocuple and RTD input)

- Automatic cold point compensation in thermocuple inputs

- Automatic line compensation in RTD connections

- Scale setting and point position selection for universal input and other 4 ... 20mA input

- Different alarm options

- On-off delay time for alarm functions

- Display point position selection

- Process value offset

- The ability to easily change and program set values on the front panel

- Optional RS-485 RTU / ASCII MODBUS communication

| Dimensions |

48x96 mm |

| Indicator |

2x4 digits, Top Display: 14mm, Bottom Display: 10mm |

| Process Input |

Universal Process Input 4 ... 20mA, 0 ... 20mA, 0 ... 60mV, 0 ... 10V Thermocouple (J, K, R, S, T) PT-100 (Line compensated) |

| Accuracy |

%0.3 |

| Control Output |

2 Relay Outputs (8A @ 250Vac) |

| Analog Output |

4...20mA, 0...20mA |

| Communication |

RS485 Modbus RTU/ASCII |

| Power Supply |

220Vac, 24Vdc, 12Vdc (It must be specified in order.) |

Universal Input Process Controller Device (VF-UPC49-2200)

EN

EN